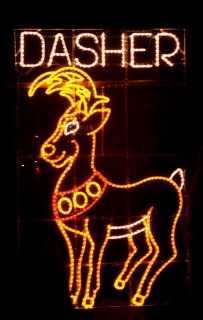

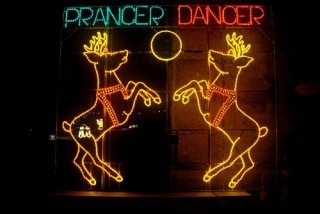

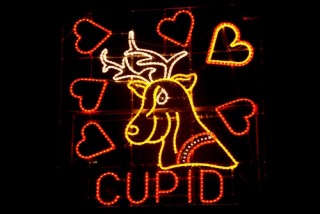

Christmas Lights

Angarrack Inn | Harvest Supper Dates for your Diary | Bible Christian Chapel, St Peters Street, St Ives

Harvest Supper Dates for your Diary.

Monday, September 29th7.00pm, at Angarrack, Harvest Songs of Praise and Pasty Supper.

Treasure Hunt and BBQ - Friday 27th June 2008

Come and join us on Friday 27th June 1008 for a fabulous Treasure Hunt and BBQ in the grounds of the Angarrack Inn by the river.

The Treasure Hunt starts at 6pm in the Angarrack Inn carpark, entry is via a small donation to the Christmas Lights fund. read more »

Duck Race - Saturday 24th May 2008

The 2008 Angarrack Duck race was a great success with an excellent turnout.

There were strong races in all categories - the Under 7's, Under 11's, Teenagers, Adults - including the 10 Men who won't cheat race!, all topped off with a Champions Race as all the winners of the previous races battled it out to become Angarrack Duck Race Champion 2008. read more »

Angarrack Christmas Lights

Angarrack Christmas Lights started a long time ago - in 1986 (see our Thirty Years page for more information) but really started to increase in complexity with the switch from bulbs to rope lights after the flooding of the village New Year 2003.

There are a variety of lights - many of the lights are animated - and the sequence of the Twelve Days of Christmas.

The main lights are designed and made in the village and are unique to Angarrack.

The Twelve Days of Christmas sequence was built up as funds allowed and completed in 2010 with Twelve Drummers Drumming. read more »

How can I help support the Angarrack Christmas Lights?

The Angarrack Lights committee are grateful for any and all help towards the support of the lights.

Options to support the lights include read more »