National Explosives, Gwinear-Gwithian - 1463206 | Historic England

National Explosives

Overview

- Heritage Category:

- Scheduled Monument

- List Entry Number:

- 1463206

- Date first listed:

- 05-Jun-2019

- Location Description:

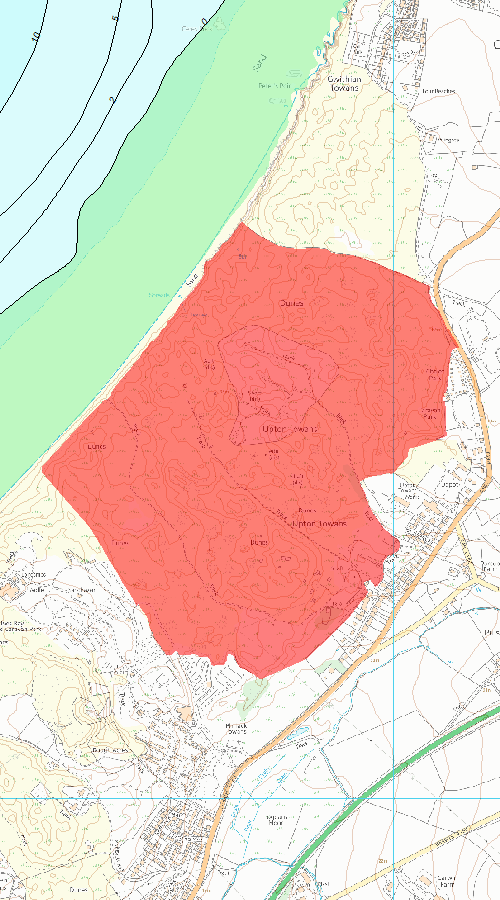

- Within the sand dunes at Upton Towans, bordered to the south-west by St Ives Bay Chalet and Caravan Park, to the north-east by Gwithian Towans, by Loggans Road to the south-east, and St Ives Bay to the north-west. NGR centred: SW5770140051.

Map

© British Crown and SeaZone Solutions Limited 2019. All rights reserved. Licence number 102006.006.

Use of this data is subject to Terms and Conditions.

The above map is for quick reference purposes only and may not be to scale. For a copy of the full scale map, please see the attached PDF - 1463206 .pdf

The PDF will be generated from our live systems and may take a few minutes to download depending on how busy our servers are. We apologise for this delay.

This copy shows the entry on 25-Jul-2019 at 17:57:51.

Location

The building or site itself may lie within the boundary of more than one authority.

- Location Description:

- Within the sand dunes at Upton Towans, bordered to the south-west by St Ives Bay Chalet and Caravan Park, to the north-east by Gwithian Towans, by Loggans Road to the south-east, and St Ives Bay to the north-west. NGR centred: SW5770140051.

- District:

- Cornwall (Unitary Authority)

- Parish:

- Gwinear-Gwithian

- District:

- Cornwall (Unitary Authority)

- Parish:

- Hayle

- National Grid Reference:

- SW5755740070

Summary

Former explosives factory begun in 1887 for the National Explosives Company, with alterations and additions until its closure in 1920.

Reasons for Designation

The former National Explosives factory at Upton

Towans, Hayle, which opened in 1889, is scheduled for the following

principal reasons:

* Period: National Explosives characterises

an uncommon example of an explosives factory built in the late C19 on a

new site but utilising its natural components, originally built to

supply the mining industry, but later as a supplier to the Royal Navy in

the First World War;

* Rarity: the factory was designed on

Continental methods under the direction of the Hungarian engineer, Oscar

Guttmann, and it may be the only example of his planning nationally

where all the component forms of the process can be read. The 1890s mass

concrete magazines are thought to be the only surviving group of their

date and type nationally;

* Survival: despite some losses, the

extensive archaeological remains provide an illustration of the layout

and organisation of the site on Continental methods, including packaging

and distribution and the factory’s growth to provide Cordite MD for the

Royal Navy in the First World War, and this contributes significantly

to our understanding of the scale and nature of explosives manufacture

in the late C19 and early C20;

* Documentation: the site is well

documented in a number of archaeological reports and publications on

the explosives industry, and historic photographs survive of the factory

in use, including of the people who worked there.

History

The National Explosives Company was an offshoot

of the Cornish Kennall Vale Gunpowder Company established near

Ponsanooth in 1811, which reached its peak in 1875 but gradually

declined with the introduction of nitroglycerine-based high explosives.

Dynamite became the most effective explosive to be used in mining and

quarrying, the sole supplier being Nobel; they held the manufacturer’s

patent until 1881 when the Privy Council dismissed their application for

its renewal, allowing production by other companies. In 1887 Kennall

managed to raise sufficient funds to set up a dynamite factory called

National Explosives, and employed Oscar Guttmann to choose a site,

design its layout and employ and train its first staff. Guttmann

(1855-1910) was a Hungarian industrial chemist and consulting engineer,

who worked at many explosives factories on the continent (including

Nobel) before moving to Britain in 1883, where he became naturalised in

1894. National Explosives was his first major commission in the country

when he accepted a position as consultant and director.

A site

in the dunes at Upton Towans north of Hayle was chosen for the National

Explosives factory in 1887. The nearby expanding market in mining and

quarrying and the potential for dynamite to replace gunpowder; access to

engineering skills in the foundries of Hayle; and proximity to a

shipping port and the national railway network were reasons for locating

it here. Additionally, since the components of dynamite (nitroglycerine

and guncotton) are volatile and highly explosive, the sandy dunes of

Upton Towans – away from the populated area but close enough to attract a

workforce – provided natural screening to confine the effects of an

accident. The natural landscape was also found to be efficiently

adaptable for the factory’s safety requirements.

The

construction of the factory began in 1889 after two years of planning;

the first batch of dynamite was produced in December that year. The

construction of the buildings was undertaken by James Julian of Truro,

and the machinery provided by Holman Brothers of Camborne. The factory

comprised two main sections. The ‘danger’ area within the dunes was

divided using a Continental approach into a ‘wet’ area for making and

storing nitroglycerine, and a ‘dry’ area where the material was

processed into marketable explosives. The topography of the dunes was

used for the falling levels of the nitroglycerine factory, resulting in

the main manufacturing area being at the highest points in the dunes,

named Jack Straw’s Hill. Workers in the danger area had to pass through

special changing and search rooms to ensure they were wearing the

correct clothing and carried no prohibited articles which could be

dangerous with explosives. A services area at the south-east of the site

comprised steam boilers, a steam-driven air compressor, electric

generators and extensive laboratories, workshops and stores. Substantial

houses were also built for management employees along Loggans Road. The

factory was managed by JW Wilkinson, with William ‘Billy’ Bate

appointed as chemist-in-charge and manager of the danger area. Separate

foremen were chosen and trained by Guttmann for the wet and dry sides of

the danger area. Staff training and human relations were carefully

attended to, and the factory became well-known for its pleasant working

conditions from the start. Initially the factory employed 175 people and

by the end of 1890 was producing three tonnes of dynamite daily.

The

factory was the most up-to-date possible, with Guttmann selecting the

most recent and efficient Continental method for making dynamite. A

first-class nitric acid factory comprising eleven cast-iron retorts set

in brick coal-fired furnaces was built to Guttmann’s specifications to

produce the volatile form required. Sodium nitrate was tipped into a

store house, from where it was mixed with sulphuric acid and heated to

form nitric acid before collection through a condensing process in

earthenware pots. From here a mixture of nitric and sulphuric acids were

blown by compressed air up a pipe to a storage hut in the wet area at

the summit of Jack Straw’s Hill. The nitroglycerine was made by

combining glycerine and the mixed acids in a nitrator, a lead vessel

packed with coils carrying cold water for cooling and pipes for

compressed air for stirring, enclosed in a wooden container. The mixture

of waste acid and nitroglycerine was run into a separator located in a

separate hut through open timber gutters on timber trestles, where after

a period of precipitation the acids were drawn off by gravity from the

nitroglycerine. This was an improvement on previous methods where the

nitroglycerine was skimmed off by hand. After washing and filtering in a

further hut, the nitroglycerine was held in stores at the foot of the

hill before being transported in rubber buckets to a mixing house, where

it was hand-mixed with kieselghur (a form of diatomaceous earth),

prepared from raw in the service area. It was then moved to the

cartridging huts where it was extruded using hand-operated cartridging

machines by three or four women in each hut to produce sticks of

dynamite, wrapped in parchmentised paper and packed into wooden crates.

The

buildings in the danger area were small and well spread-out amongst the

dunes. Massive embankments (traverses) were built from the sand to

screen the timber buildings from each other and to direct the force of

any explosion upwards, rather than outwards. The large volume of water

required by the factory was pumped from a shaft at the former Boiling

Well Mine at the south-west of the service area. The buildings were

heated by steam carried in lagged pipes on overhead trestles to ensure

that the nitroglycerine did not freeze. Extensive planting of marram

grass was undertaken to stop sand blowing off the dunes. By late 1890

the factory was fully operational, with dynamite being sold through the

Kennall gunpowder agencies, including export outside of Cornwall, and as

far as Australia.

In 1891 the factory was extended for the

manufacture of gelatinous nitroglycerine explosives. This included a new

factory in the non-danger area for nitrating cotton to make collodion.

Cotton waste was imported from Lancashire, nitrated in a mixture of

acids, and pushed into earthenware pots made by Doulton & Co. The

cotton was spun to remove the excess acid, immersed in water, and taken

to a boiling house where it was digested with several changes of

steam-heated water. In a pulping house it was chopped up into slurry,

spun and bagged and taken to a drying house. Once the cotton was dry it

was taken to the mixing houses in the danger area where it was combined

with nitroglycerine and an absorbing powder comprising potassium nitrate

and woodmeal. This produced one of the standard gelagnites used in

Britain in the 1890s.

In 1894 National Explosives embarked on a

venture to build a cordite plant, a new gun propellant made from a

mixture of guncotton, nitroglycerine, acetone and vaseline. The

expansion of the factory included a larger guncotton plant with drying

stoves, cordite mixing houses and press ranges. The Government’s plant

at Waltham Abbey had only just also started production and was not

deemed to be able to produce the amount required by the Royal Forces.

New equipment was needed to make the full range of sizes of cordite for

the Government, and the factory fell under strict regulations. In the

late C19 National Explosives was manufacturing MK1 cordite and became

its leading manufacturer as contracts rolled in. 200 people were

employed at National Explosives at this point, but it was soon to

expand. In October 1901 National Explosives - by now a company in its

own right - adopted cordite MD, which was smokeless and had less

nitroglycerine and more acetone. This expansion in cordite production

also resulted in the construction of a new nitroglycerine factory to the

west of Jack Straw’s Hill in 1905; this became known as New Nitro Hill.

Influenced by an explosion in a wash house on Jack Straw’s Hill a year

earlier, it was laid out on ‘clean lines’, comprising one nitrating

house, one separating house and two storage houses for washing,

filtering and precipitation. New cartridge huts were built at the

eastern base of the hill and a new guncotton section built to the east

of the nitric acid factory. National Explosives reached its maximum

capacity for the manufacture of blasting explosives in 1907, when it was

producing around 1000 tonnes a year of cordite, plus 2000 tonnes of

other explosives.

During the First World War Cordite MD was

insisted on by the Royal Navy; National Explosives and one other plant

were their main suppliers until nearly the end of the war. The acetone

used in its production was scarce, previous supplies being imported from

Germany, so the factory built its own acetone recovery plant. This

further increase in activity resulted in the need for new plant at the

factory, much of which was supplied by Holmans. A standard gauge railway

line to the site from the Great Western line in Hayle was also built,

complete with a large shed for loading the finished explosives into

railway vans. At its peak during the First World War the factory’s

workforce rose to 1800. Soldiers patrolled the Towans, and four men were

employed to specifically maintain the sand traverses and plant marram

grass. The large female workforce was looked after by three matrons.

Although

there were undoubtedly accidents within the factory, the most

significant explosion occurred on 5 January 1904 when five employees

died and many others were injured. It was reported that the explosion

was felt up to fifteen miles away. The explosion was ruled to be caused

by the timber and lead tank lid being dropped into the nitroglycerine in

one of the precipitating houses, the reaction running to the washing

houses along the charge of nitroglycerine in the gutter between them. In

1916 two female and two male workers were killed in an explosion, but

the cause was never discovered as the factory was wrapped by strict

security regulations during the First World War.

After 1919 many

of Britain’s explosives factories were forced to close, having been

faced with over-capacity at the end of the war. Nobel once again became

the dominant force, rationalising the industry by taking over Curtis’s

and Harvey (who in turn had bought out Kennall Vale before the War). By

this point National Explosives had been established as a company in its

own right and several options were pursued to enable them to continue.

Eventually in 1920 they were taken over by Nobel and the factory was

dismantled, the large amounts of unwanted cordite in the concrete

magazines being destroyed in huge bonfires.

The 1907 Ordnance

Survey map (1:2500) shows the site in detail, prior to its expansion

during the First World War. A Trevithick Society publication ‘Cornish

Explosives’ by Bryan Earl was published in 1978 in which National

Explosives features heavily, including a lengthy description of the

explosives manufacturing process. In 1991 the site underwent an

archaeological assessment by Brian Earl and John R Smith of the Cornwall

Archaeological Unit for Cornwall County Council; much of the site’s

history was based on Earl’s earlier publication. The site was reassessed

in 1998 by Andy Jones for Cornwall Archaeological Unit. National

Explosives was included in the English Heritage publication ‘Dangerous

Energy’ by Wayne D Cocroft in 2000, and a large number of aerial

photographs were taken in 1994 as part of the research project. Other

aerial photographs from reconnaissance flights in the Second World War

and the mid-C20 are held by the Historic England archive. The site was

mapped as part of the National Mapping Programme between 1999 and 2001.

Details

The former National Explosives factory is located

in the sand dunes of Upton Towans, approximately two miles from Hayle

town centre, on the north coast of Cornwall overlooking St Ives Bay. The

monument includes the earthworks, buried remains, foundations and ruins

of the former National Explosives factory, covering an area of

approximately 663 acres (268ha). The factory was built within the

natural dunes of Upton Towans from 1889 and closed in 1919. It comprises

one area nearest the sea, the ‘danger’ area within the sand dunes; and a

service area off Loggans Road. As the factory expanded in the C20,

further buildings were constructed and services updated. The danger area

principally retains the remains of the sand traverses; there are also

some concrete foundations on New Nitro Hill and the roofless remains of

four mass-concrete magazines at the north of the site. The service area

retains concrete foundations for the boilers and steam engines, and the

nitric acid factory remains as a roofless brick shell.

A lengthy

description of this site is beyond the scope of this document and is

covered in detail by Earl (1978), Earl & Smith (1991), Jones (1998)

and Cocroft (2000) from which the following summary draws. This

description does not attempt to describe every feature present, but

rather will characterise briefly the remains in each area.

DESCRIPTION

As a factory dealing with dangerous materials, safety was of paramount

concern. The buildings in the danger area of the site were protected by

sand traverses, either using the natural form of the sand dunes or by

creating new ones, planted with marram grass to improve their stability.

For the site to operate efficiently between the two areas, and for

transport of products in and out of the site, a narrow-gauge tramway ran

from the service area to all areas of the process. Its route led past

the cartridging huts at the foot of New Nitro Hill, and the remains of

an incline can be found on the east side of New Nitro Hill itself. Part

of the railway platform survives within the service area of the factory.

Service area

The service area covered approximately 16 acres (6.5ha) and contained

the largest number of built structures on the site. To the north-east

was located the acid recovery plant, nitrocotton works and nitric acid

works with its chimney. The ACID RECOVERY PLANT and NITROCOTTON WORKS

survive as a series of concrete bases, the longest of which is

approximately 40m long and surrounds a level platformed area with a

concrete floor. At the south-east end is a sunken area 6m wide, 24m long

and up to 1m deep containing engine-mounting blocks. Moving south-west

the NITRIC ACID WORKS comprises the main brick-built FACTORY and former

STORE. The latter is a concrete structure surviving to gable height with

iron girders forming the roof rafters. It is divided into three

sections, each 5m long, with a doorway and window on opposite walls.

Attached to this building is the nitric acid factory: a brick-built

building, 17 bays long defined internally by brick pilasters. It is

roofless and has a number of windows and openings with segmental-arch

heads. Within the interior is a brick surface incorporating sub-floor

flues, the main flue runs 0.8m away from the south-west wall and is

0.75m deep by 0.75m wide. The bricks making up the floor of the

buildings are stamped with OBSIDIANATE ACID PROOF BRICKS. Surrounding

the former nitric acid works factory are various flues and channels,

walls and floors related to the processes taking place in the factory.

To

the south-west are the principal service buildings for the factory. At

the northern end lie the remains of the PROCESS NITROCOTTON WORKS (as

identified by Earl, 1978). It is constructed of brick with a brick and

concrete floor, and surrounded by demolished fabric and earth up to 2m

high. The interior contains large sunken tanks up to 1.75m deep. To the

east is a former mine shaft known as KING’S SHAFT; it was historically

part of Boiling Well Mine and was adapted for use by the National

Explosives Company as a source of water. Adjacent to the shaft is a

concrete WALL 1m wide, 5.5m long and 0.6m high with metal bolts sunk

into it, and was probably the housing for a pump. At the far south-west

end of the area is a derelict HOUSE, marked on the 1907 Ordnance Survey

map as Hillside Cottage, but was also known as Pearce’s Cottage. It is

constructed of brick and stone with granite quoins and may be one of the

earliest buildings associated with the factory. Alternatively it may

have been associated with Boiling Well Mine. To the north are the

remains of the ENGINE HOUSES which provided power to the service area.

An earthwork feature in this area is a sand TRAVERSE divided into three

bays by two sand-covered banks; the northern bay is 3m wide by 12m long

and contains two concrete slabs approximately 0.5m wide and 1.5m apart.

This bay is separated from the central bay by a bank approximately 2m

high and 5m wide. The north side of its entrance is revetted with

mortared stone and brick. The central bay is in line with the entrance

and is 2m wide and 10m long, separated from the southern bay by a bank

1.6m high by 8m wide. The southern bay is 3m wide and 10m long and

contains two concrete slabs. The western end of the structure is a sand

dune several metres high. To the west are a series of six parallel

concrete ‘sleepers’ which would have formed the BASE of a structure.

They are set in an excavated area and form a rectangular area 7.5m wide

and 9m long; each slab is 0.4m high and 0.4m wide. This is a common

feature across the entire site and a further example 7.5m square with

the concrete strips being 0.7m high and 0.5m wide lies 44m to the

north-east of here.

Jack Straw’s Hill

Jack Straw’s Hill covers an area of approximately 24 acres (10ha). Its

principal features are two CORDITE PRESS enclosures. The one located at

the far north-east of the area comprises a rectangular open-ended

traverse with an interior measuring 11m wide and 44m long. Along the

north-western side of the interior is a line of four concrete plinths

1.6m wide and 2m long. In the centre of the structure is a concrete

plinth 0.6m wide, 1m long and 0.7m high. The surrounding bank is up to

4m high. The second enclosure is near to the service area, on the south

west side of this area. It comprises a long bank running north-east to

south-west, 2m high and 7m thick. Along the northern side of the bank

are a series of concrete footings which extend out from the bank for a

distance of around 5m. At the eastern end of the bank are traces of

another range of building footings which run roughly north-west to

south-east, up to 10m wide and 40m long. At the western end of the bank

is a concrete wall running north-west to south-east, 10m long and 1m

high, with a flight of steps at its northern end. Around this area are

many sand TRAVERSES and BUILDING PLATFORMS between 9m and 17m square,

with the traverses having banks up to 2m high. The principal processing

area at Jack Straw's Hill comprises an area of traverses each with a

defined role in the nitrating process. The nitrating enclosure was also

known as THE CASTLE, at the summit of the hill, where glycerine and acid

were mixed. It is a 10m square traverse with the banks being 2m to 3m

high. To its north is the area for SEPARATING/PREWASH, consisting of a

U-shaped traverse 3m high encircling an area 15m long and 10m wide.

Immediately to its west is a further traverse used as a STORE, again 10m

square with banks 3m high on the east and west sides and 4m high to the

south and 1.5m high to the north. A further SEPARATING/PREWASH

enclosure is identified by a BUILDING PLATFORM 3.5m square, which

contains two concrete slabs 0.3m by 0.3m and 2m apart. The platform is

sheltered on the west and south sides by sand banks 3m to 4m high. A

NITRATING ENCLOSURE is located to its east, cut into the dunes on three

sides and open on the east side. It is 10m square and contains six

concrete sleepers 10m long by 5m wide and high, placed approximately

0.7m apart. The product was then moved from the prewash to the FINAL

WASH: a complex of two traverses one of which is a 13m square

featureless enclosure, and one a sunken enclosure 8m to 9m square cut

into the dunes at a depth of 6m, which held a DROWNING TANK. The WATER

WASH DEPOSIT was located to the west of the summit of the hill,

comprising a 12m thick L-shaped bank defining an area 9m square, with

banks 3m to 4m high. To the south of the hill, and at the lowest point

in the process, is the SEPARATING area, comprising two traverses one of

which has an interior 19m wide and 28m long, with its north and west

sides defined by an L-shaped bank up to 6m high, and a 4m high bank on

the southern side. The second traverse has its east side defined by the

first, and measures 12m square, with banks between 1.5m and 2.5m. Both

enclosures contain concrete sleepers. A further STORE is located at the

south-western corner of the area, approached by a sunken CAUSEWAY 26m

long, 5m wide and 3m deep. The traverse structure is 10m wide and 14m

long, with an internal sunken area 6m wide and 1m deep. The banks are 4m

high.

New Nitro Hill

This area covers the south-west half of the site and is approximately 27

acres (11ha) in size. On the south and west side of this area are a

series of traverses, historically containing timber buildings used as

GUNCOTTON DRIES. Most are approximately 9m by 12m, with 8m thick banks

which vary in height but are around 3m to 4m. Each has a gap in one bank

for an entrance, varying in width from 1.5m to 5.5m. A group of three

traverses lie to the south of a former tunnel (shown on the 1907

Ordnance Survey map and possibly built to protect the cartridge huts)

which is now a deep embanked causeway. The three traverses are linked in

a ‘T’ shape by embanked causeways 2m wide by 1.8m wide. Most of these

traverses are featureless internally but some retain a concrete platform

or blocks of masonry. To the north-west are a series of smaller

traverses which would have held CARTRIDGE HUTS. There are 14 in this

area and they vary in size (on average 6m square), but all have one low

bank approximately 2m high with taller banks between 4m and 10m high on

the other sides. No features remain internally. On the east side of this

area at the summit of the hill, which rises to 56m, are three building

platforms comprising five, ten and eleven concrete sleepers, 9m to 13m

long, with each sleeper being up to 0.7m high. There are a further two

platforms to the north-west. These were the FOUNDATIONS for concrete

tanks for holdings the acids and glycerine. At the foot of New Nitro

Hill on its north-east side is a line of square traverses running

north-west to south-east along the line of the former tramway. These

traverses would have held CARTRIDGE HUTS; the 1907 Ordnance Survey map

shows 12 huts in the range and 11 survive in readable form. They vary in

size (on average 6m square) and all have banks 2m high. An INCLINE of

the tramway made up of bituminous pads, runs from a junction to the east

to the summit of the hill for approximately 150m.

Magazines

area

This area is located closest to the sea and covers an area of

approximately 87 acres (35ha). Around this area are many sand TRAVERSES

some of which have internal concrete plinths and would have contained

small timber buildings used as MAGAZINES, CORDITE DRIES and CORDITE

STORES. Some are massive: for example where the topography flattens out

at the base of Jack Straw’s Hill and near to a WALL, designed as a

blast-proof barrier, 10.5m long and 1.6m high constructed of brick and

scoria blocks. Here there are two traverses 15m and 16m square, with

man-made banks up to 3m high with one side backing onto dune material up

to 5m high. To the north of here, the traverses vary in size from 12m

to 15m square, to structures from 16m wide to 24m long. Each has an

entrance and the surrounding banks are 2m to 3m high, some being cut

into or having natural dunes to one or more sides. Natural sand dunes

are present in the far north-east corner of this area. On the west side

of this area are four mass-concrete MAGAZINES or store houses. The

structures are roofless and are set in sunken areas and/or enclosed

within traverses. The buildings are roughly 8m by 9m with side walls 2m

high and the gable ends 4m high. Each has two or three arch-head windows

on the gable-end walls. The demolished remains of a further magazine

are also present.

EXTENT OF SCHEDULING

The extent of the site is defined by the coast of St Ives Bay to the

north; to the boundary to St Ives Bay Chalet and Caravan Park to the

south-west; to the north-east by Gwithian Towans; and to the south-east

by the boundary to the rear of properties and industrial works along

Loggans Road.

EXCLUSIONS

The chimney to the nitric acid works, all modern signage, fencing and

gates, safety structures (steel gates and grilles), and modern road and

track surfaces are excluded from the scheduling, although the ground

below them is included.

Sources

Books and journals

Cocroft, W, Dangerous Energy The Archaeology of Gunpowder and Military Explosives Manufacture, (2000), 144-146

Earl, B, Cornish Explosives, (1978), 184-251

'Summer Meeting August 30th 1913' in Transactions of the Cornish Institute of Engineers, , Vol. 1, (1913), 95-103

Websites

Hayle Community Archive , accessed 19/02/2019 from http://www.communitycatalogues.co.uk/view_a__24_or__1065.aspx

Heart of Conflict: Munitions’ factory deaths remembered in Hayle , accessed 19/02/2019 from https://www.heartofconflict.org.uk/munitions-factory-deaths-remembered-in-hayle/

Heritage Gateway – Hayle Towans post medieval explosives factory, HER number 37085 , accessed 19/02/2019 from https://www.heritagegateway.org.uk/Gateway/Results_Single.aspx?uid=MCO28594&resourceID=1020

Pastscape – The National Explosives Company, monument number 1310585 , accessed 19/02/2019 from https://www.pastscape.org.uk/hob.aspx?hob_id=1310585&sort=2&type=&typeselect=c&rational=a&class1=None&period=None&county=None&district=None&parish=None&place=&recordsperpage=10&source=text&rtype=monument&rnumber=1310585

Penwith Local History Group: Perfect Jelly at Dynamite Towans , accessed 19/02/2019 from http://www.penwithlocalhistorygroup.co.uk/on-this-day/?id=216

Upton Towans and the National Explosives Company , accessed 19/02/2019 from https://www.qsl.net/2e0waw/upton_towans.htm

Other

Aerial photographs (oblique and vertical) from Historic England Archive

Earl, B & Smith, JR, National Explosives, Upton Towans, Hayle: an archaeological and historic assessment, 1991.

Jones, A, Upton and Gwithian Towans: an archaeological assessment of the Cornwall County Council Countryside Services, 1998.

Jones, A, Upton and Gwithian Towans: structural recording work, 1999.

Ordnance Survey, Cornwall (1907) (1:2500).

Royal Cornwall Gazette, Terrible Explosion at Gwithian, January 7 1904, pp4-5.

The Cornishman, The National Explosives Works at Hayle Towans, September 19 1895, p6.

Young, A, Cornwall and Isles of Scilly Mapping Project: a report for the National Mapping Programme, October 2007.

Legal

This monument is scheduled under the Ancient Monuments and Archaeological Areas Act 1979 as amended as it appears to the Secretary of State to be of national importance. This entry is a copy, the original is held by the Department for Digital, Culture, Media and Sport.

End of official listing

via

- Printer-friendly version

- Login or register to post comments

- Permalink

Contributions

- Angarrack Defibrillator Team (25)

- Angarrack Inn (336)

- Angarrack Methodist Chapel (3)

- Carol (15)

- Gail (1)

- GordonG (12)

- Hayle Development Group on Facebook (5)

- Hayle Harbour Authority (4)

- Hayle Town Council (5)

- louise (1)

- Lynne (94)

- Mal (1)

- Neil (22)

- Neils Garden Care (9)

- Russell (21)

- Secretary - Christmas Lights (118)

- Steve (3)

- webmaster (5023)

Book page

Similar

- Dynamite Towans

- 190129 | Will the authorities ever learn what causes those Subterranean Hayle Stink Blues?

- 190130 | Cornwall Council admits defeat and calls for help in bid to solve the Hayle underground water mystery

- 181101 | These are the buildings and monuments given Grade II listings in Cornwall

- 170726 | Tools from Cornwall’s first farmers among important archaeological finds at Hayle construction site (From Falmouth Pack

Similar across site

- National Explosives, Gwinear-Gwithian - 1463206 | Historic England

- Dynamite Towans

- 190129 | Will the authorities ever learn what causes those Subterranean Hayle Stink Blues?

- 190130 | Cornwall Council admits defeat and calls for help in bid to solve the Hayle underground water mystery

- 181101 | These are the buildings and monuments given Grade II listings in Cornwall

Be the first to contribute